Our Brands

Innovation without Limitation

When we began our journey toward the future of manufacturing, one thing became clear: an unprecedented network of support and innovation was required to overcome production challenges and excel in medical device manufacturing and beyond.

To achieve this MMT aligns brands, products, and people to deliver high-quality, precision results for our customers. We bring in-depth experience and wide breadth of knowledge of machining and operations to every project. Our team of experts have proven histories of performance, leadership, and deep-seeded technical expertise. Each of our brands boast long-term, comprehensive customer and supplier partnerships.

Your sole source solution for automated, process-driven medical manufacturing.

Leading provider of catheter balloon forming, folding and pleating, thermal bonding, and stent crimping solutions.

Leading designers of medical device manufacturing equipment & automation support services.

Our MMT Family

Glebar

A Long History of Innovation

Founded in 1952 by Miner Gleason and Robert Barhorst, Glebar was established to manufacture machine tools based on the principles of centerless grinding. Located in Ramsey in Northern New Jersey, our expertise in manufacturing has supplied our customers with custom solutions incorporating the latest technology, and produced equipment that provides an efficient and controlled manufacturing process.

Over half a century in operation, Glebar has helped customers to drastically improve throughput, while enhancing the quality of their products and the efficiency of their operations. Glebar’s innovations have replaced alternative technologies such as lathes, OD grinders, and Blanchard grinders, with precision, high-volume production turnkey systems. We collaborate with our customers to integrate our systems into their processes, and effectively streamline their production. Over the years, Glebar has designed and manufactured an array of machine tools for its customers: centerless grinders, form grinders, gauging systems dressing machines and other microgrinding systems.

Syneo

Synergy in Product Integration and Innovation in Technology

SYNEO’s medical manufacturing products and services focus on solving some of the largest manufacturing problems for some of the smallest of minimally-invasive device applications. SYNEO machine, cutting tool, and specialty manufacturing services target the automation of cutting, feeding, slitting, flaring, grinding, skiving, printing, punching, assembly, and hole drilling of device components such as catheters and guide wires as well cutting and coring applications of human tissue.

SYNEO is the product of the 2011 merger of two industry peers – ASG Medical Systems and Technical Innovations – combining medical manufacturing automation and precision hole making expertise into a single entity. SYNEO is a machine automation and tooling services company that is headquartered in West Palm Beach, Florida USA, with manufacturing locations in Florida and Angleton, Texas and forward-deployed sales and service offices in Galway, Ireland, and Shenzhen, China.

CATHTIP

Focused on Catheters for Over 15 Years

Focused on Catheters for Over 15

Years

CATHTIP’s catheter tipping and hole punching machines, dies, drills and tooling are proudly made in the U.S.A., since 1995. Our catheter specialty manufacturing supports low and high volume runs and is integrated with our engineering and development teams, as well as in-house machine shop, to ensure quality, service and reliability.

Capable of tip forming, flaring or bonding almost all thermo-plastic materials to exacting standards, our catheter tipping machines can be seen producing flashless tips in the cleanrooms of the largest medical device manufacturers, as well as those of small R&D labs, worldwide.

Engineering By Design

Internationally Recognized Precision

Founded in 1985, Engineering By Design (EBD), has successfully developed hundreds of machines and products used in a variety of industries. In fact, EBD has an international presence with machines in Puerto Rico, Mexico, and Japan.

Engineering By Design is one of the nation’s premiere machine builders. We serve industries from medical to nuclear, from companies that face extreme environments to companies that demand the highest levels of technology.

As a trusted developer of coil winding machines and patented catheter laminators, EBD leads the industry in both precision and speed, and we are proud to state that our catheter laminators have revolutionized medical production.

R&D Engineering

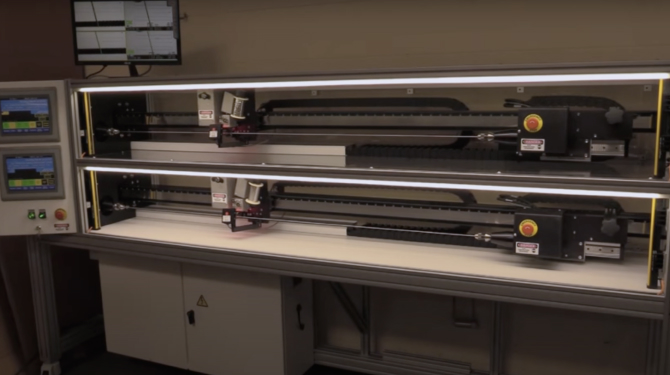

Streamlining Med Device Manufacturing since 2001

R&D Engineering’s Cath-Tech machines are used by many of the world’s largest medical device companies and include catheter reflow, tipping, bonding, flaring, swaging, hole forming, pullers, cutters, and balloon manufacturing processes. RDE provides engineering, quality, installation, and automation support services.

MPT Europe

Machines for Catheter & Stent Manufacturers

Founded in 2005, Medical Production Technology Europe (MPT) is a global leader of balloon forming, folding and pleating, thermal bonding, and stent crimping solutions. With a strong background in mechanical engineering and automation, MPT brings a highly valuable, unique insight and know-how to the manufacturing process in the medical market.

TRIDEX TECHNOLOGY

Burr-Free Electrochemical Grinding & Cutoff Manufacturers

Tridex Technology provides manufacturing companies around the world with burr-free Electrochemical Grinding (ECG) and Cutoff solutions. Producing a burr-free cut or grind, ECG eliminates the need for secondary operations such as deburring, helping to increase productivity and output while reducing downtime. Conveninetly located in Pennsauken, NJ, Tridex provides expert application design, machine solutions, and unmatched service. In 2020, Tridex was acquired by Glebar, world leaders in centerless grinding technology.

Interface

Comprehensive Balloon Production & Testing Solutions

Building Strength Through M&A

In the highly fragmented manufacturing industry, we believe strategic mergers and acquisitions drives innovation by providing a platform otherwise unattainable.

At MMT, our M&A approach identifies brands with highly competitive market positions that fit well in our culture of creative innovation. We target organizations that challenge the norm and seek to develop new technologies and applications.

Sustainability and Cultural Change

In unprecedented times, it’s critical to use our organizational power for good. MMT is committed to environmental sustainability in its workplace and community at large. We are committed to creating a safer and more sustainable business as good stewards for the earth and champions for true diversity.

Manufacturing Made Smarter

When you need more bandwidth for a product line, more machining resources due to logistical changes, or better technology to improve your process, MMT delivers an unmatched depth of service to solve your unique and urgent business challenges.